AOTEK is leading the transformation of Human Machine Interfaces to the new Web-based, multiplatform technologies (HTML5, CSS3, JavaScript ES6, etc.) and standards. Early adoption of standards and intimate collaboration with customers lead the development of tools tailored to the specific needs of OEMs and final users of the CNCs. As examples of this orientation, the following applications are guiding our projects:

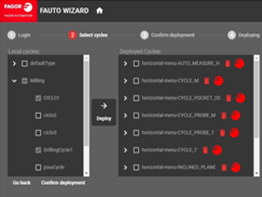

Customization tools

For the highest degree of customization, AOTEK has developed libraries and graphical applications where an OEM or even a final customer can tune not only the graphical aspects but even the behaviour of the CNC to his very specific needs. AOTEK can also support customers in their specific projects with its proved experience.

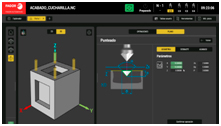

Part piece and feature oriented programming

AOTEK has lead the development of new HMIs that are not only visually appealing but directly targeted to cover the CNC operator’s needs. User experience has been incorporated very early in the design giving as result a highly usable interface where daily operation of the CNC is intuitive and aligned with effective part production.

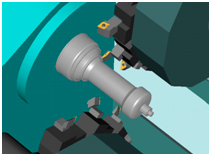

Virtual machining with realistic 3D graphics and collision detection system, Digital twin of machine and CNC

Focusing on CNC customers’ needs AOTEK has integrated a highly realistic simulator of the CNC with the look and feel of its real counterpart. This simulator can display in 3D solid graphics both the machine and the part being produced and, more important, detect collisions between tool and machine or part and machine, effectively allowing “first time right” production of very complex parts and speeding up the process from design to product.

AOTEK can support customers in translating their machines’ designs to the simulator, effectively producing a digital twin of them and leading to virtual commissioning, both in engineering and production phases.